Heats in Seconds, Built to Last: Bioinspired Solar‑thermal Fabric

Researchers from the School of Materials Science and Engineering have developed a molecular solar thermal (MOST) fabric that warms rapidly, withstands intensive laundering and abrasion, and allows precise temperature control—all without embedded electronics—according to a study in Advanced Materials.

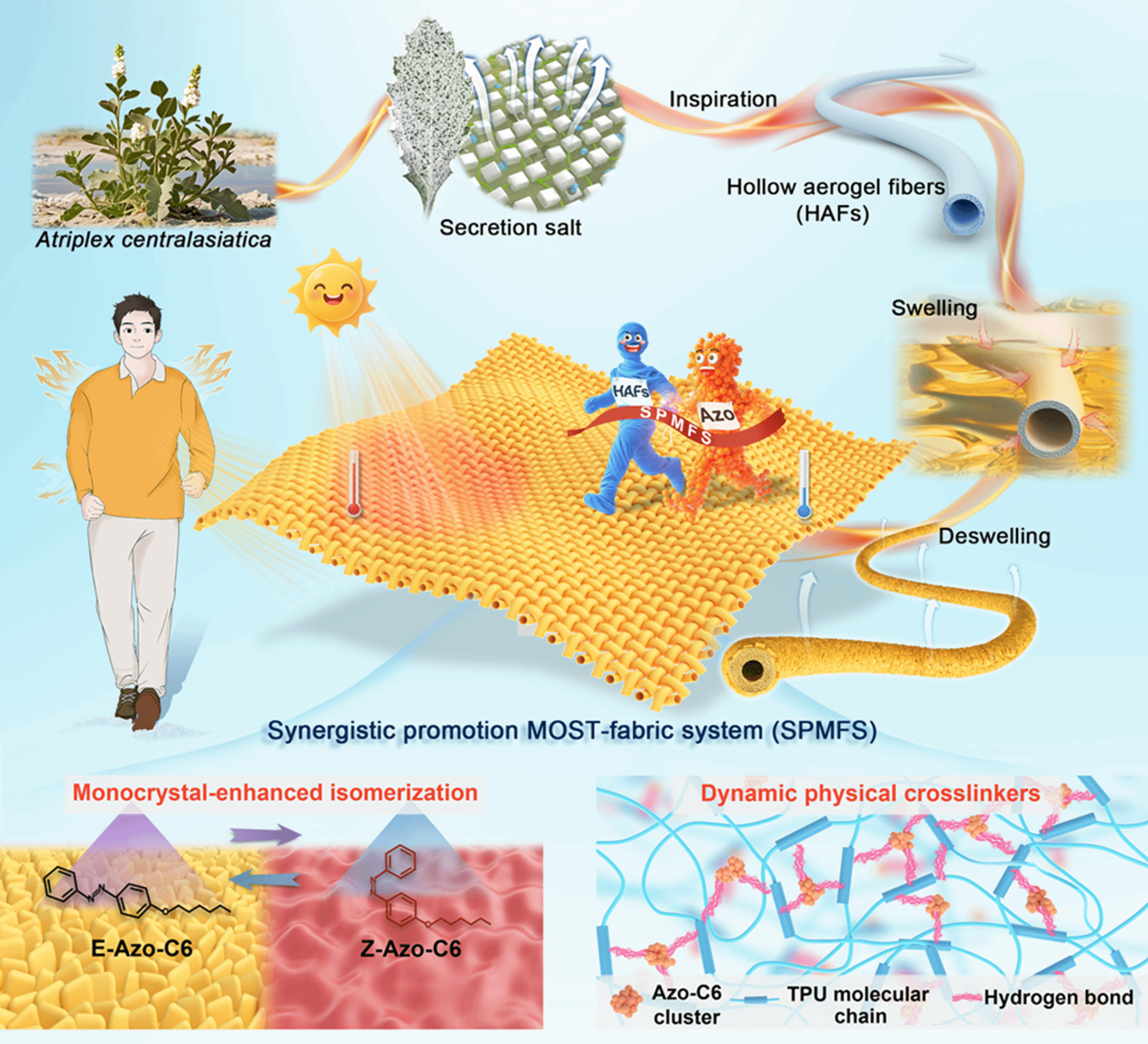

The work tackles a persistent hurdle in wearable personal thermal management (PTM): MOST molecules often mismatch with textile substrates, compromising durability and energy conversion. Inspired by the salt absorption–secretion cycle of the halophyte Atriplex centralasiatica, the team designed a swelling–deswelling process for thermoplastic polyurethane (TPU) hollow aerogel fibers (HAFs). As the fibers swell in solution and then dry, TPU chains reorganize into a densified network while azobenzene (Azo) migrates outward and forms dense, uniform monocrystalline layers on the fiber surface.

The researchers describe the result as a synergistically promoted MOST–fabric system (SPMFS). In mechanical tests, the SPMFS boosted breaking strain by 48% and tensile strength by 129% versus untreated fibers. In energy tests, it delivered greater than 94% photoconversion during photo charging and photo discharging, with a uniform areal energy density of 7.5 kJ m−2.

Benchmarks from the team’s demonstrations point to fast, programmable heating. Under 420 nm blue light, the fabric’s surface temperature rose by 25.5 °C in 70 seconds, the authors report. Even at −20 °C under simulated sunlight, it warmed by 21.2 °C within 50 seconds; in strong light, the surface can jump to around 40 °C in roughly a dozen seconds. The textile’s heat output can be tuned by adjusting light intensity, enabling localized, on demand warming for everyday comfort and photothermal physiotherapy.

Durability was a key focus. After 50 abrasion cycles, 500 stretching/bending cycles, and 72 hours of continuous washing, the fabric retained over 90% of its photothermal performance, addressing the delamination and short service life that have limited earlier MOST coatings.

“By converting a biological self adaptation mechanism into a materials design strategy, we achieved synchronized gains in efficiency and durability,” said Feng Wei, the study’s corresponding author. The authors say the bioinspired method could support scalable production of smart apparel, outdoor protective gear, and medical heat therapy aids. The study appears in Advanced Materials (see doi.org/10.1002/adma.202514043 for terminology).

By Eva Yin